The Paris 2024 Olympic Games provide an opportunity to highlight technical innovations for elite athletes. Notably, during the 1968 Winter Olympics in Grenoble, France, the French alpine ski team won eight Olympic medals, including three golds by Jean-Claude Killy. That year also showcased French expertise in manufacturing competition footwear.

Indeed, Heschung ® Workshops were the official suppliers of the French ski team. This company from northern Alsace was renowned for its mastery of Norwegian welt stitching, a variant of the "Goodyear" welt. The benefit of these stitches is to make the shoe waterproof due to the robust seams that connect the upper part of the shoe (the upper) to the sole, making it resoleable.

A Bit of History…

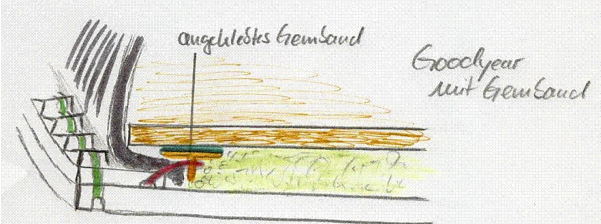

The "Goodyear" welt is the mechanized version of the welt stitch that appeared in the 15th century. This technique, by adding an additional sole, allowed shoes to be resoled. The welt stitch involves a leather strip sewn to the upper and the insole with a horizontal and invisible stitch (shown in red in the diagram below) and to the outsole with a vertical and visible stitch all around the shoe (shown in green in the diagram).

(Source : Wikipedia)

|

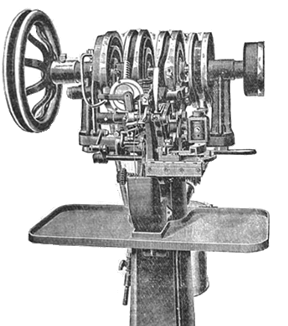

In the case of the Norwegian welt, both stitches are visible, but its advantages are comparable to those of the "Goodyear" welt. The "Goodyear" welt owes its name to Charles Goodyear Jr., son of Charles Goodyear, the inventor of rubber vulcanization. His financial support enabled inventors like Auguste Destouy and Daniel Mills to perfect the first shoe manufacturing machines and to file several patents, the first dating back to 1869 (U.S. Patent No. 96,944). |

Back to the Olympics…

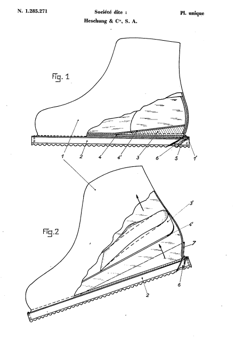

After outfitting the first skiers from the Vosges massif, Heschung turned to manufacturing competition ski boots and became the official supplier of the French ski team. Before achieving Olympic glory, they had perfected their expertise and filed two patents for ski boots in the early 1960s.

The first patent, filed in 1960, protected a new method of making ski boots by replacing the trapezoidal-shaped sole, which gives skiers the classic forward-leaning position, with an additional wedge-shaped piece of appropriate inclination (marked 3 and 3’ in the figures below from the patent). This new method of construction provides better stability and increased rigidity.

|

|

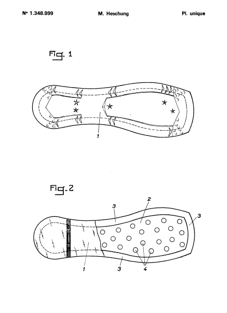

The second patent, filed in 1963, concerned a ski boot sole made by pouring a mass of rubber into which is incorporated a plate of the same shape as the sole to be obtained but narrower to leave a welding strip around the sole to the boot, which also has a plurality of cylindrical perforations into which the rubber penetrates during the casting operation. This new method of making the sole ensures particularly effective rigidity.

Other patents followed, the latest resulting from a partnership with BMW Motorrad ® for a motorcycle boot protection device. Proof that technical innovation often ventures off the beaten path!